|

From here on... |

|

Jessesen.com |

|

Work |

|

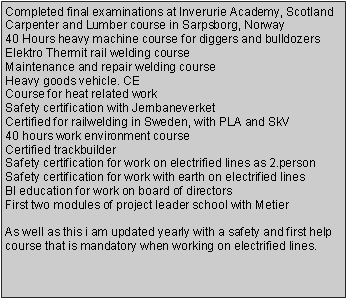

Education & Courses:

|

|

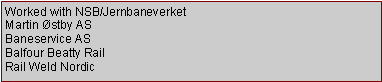

Work Experience: |

|

I have work experience from all over Scandinavia that is based on track maintenance, building of new tracks and work with heavy machines as well as being a rail welder. My recent job was site manager for the rail welding section of Baneservice.

Some key projects: 1993-Rebuild of Filipstad Station in Oslo 1996-Rebuild of Fåvang Station 1997-Responsibility for all welding between Såstad-Haug 1998-Rebuild of parts of Alnabru with tracks and switches 1999-Rail changing through the valley of Gulbrandsdalen 2000-Refurbishment of tracks at Taulov in Denmark 2001-Rebuild of Stockholm South (Station) 2002-Work on the Ofotbanen, iron ore line between Kiruna and Narvik 2004-Sandvika Station, rebuild in preparation for 4 tracks 2005-Rebuild of Asker Station 2006-Maintenance work in Oslo 2007-Railwelding at Lysaker Station 2008-Oslo Metrolines refurbishment 2008-South Varanger Mines in Kirkenes, refurbishment and maintenance 2009-Lysaker Station 2010-Stabekk Station

This is a short list of many of the projects that i have taken part in, giving me valuable experience to take into the future.

|

|

When it comes to other work experience i have sat on the board of directors at Baneservice as a representative for the employees for 5 years, this has given me valuable experience for working with strategy, budgets and restructuring.

I have also been Union leader for the largest workers union ( BFF )at Baneservice for 5 years, this also gives ample experience in working with people, cases, payrises and all other challenges that come with restructuring.

This has also given me the opportunity to work with the Norwegian Railway Association ( NJF ) |

![Tekstboks: Thermite is a pyrotechnic composition of a metal powder and a metal oxide, which produces an aluminothermic reaction known as a thermite reaction. It is not explosive, but can create short bursts of extremely high temperatures focused on a very small area for a short period of time.

Thermites can be a diverse class of compositions. The fuels are often aluminium, magnesium, calcium, titanium, zinc, silicon, and boron. The oxidizers can be boron(III) oxide, silicon(IV) oxide, chromium(III) oxide, manganese(IV) oxide, iron(III) oxide, iron(II,III) oxide, copper(II) oxide, and lead(II,II,IV) oxide. [1]

The most common thermite is aluminium-iron(III) oxide.

The aluminium reduces the oxide of another metal, most commonly iron oxide, because aluminium is highly combustible:

Fe2O3 + 2Al -> 2Fe + Al2O3 + Heat

The products are aluminium oxide, free elemental iron, and a large amount of heat. The reactants are commonly powdered and mixed with a binder to keep the material solid and prevent separation.

The reaction is used for thermite welding, often used to join rail tracks. Other metal oxides can be used, such as chromium oxide, to generate elementary metal. Copper thermite, using copper oxide, is used for creating electric joints in a process called cadwelding:

3CuO + 2Al -> 3Cu + Al2O3 + Heat](image291.png)

|

Time for a change...when coming to a crossroad and not having any idea which way to go, i have taken a chance to follow my heart. My enthusiasm for the railway and my joy for the work i do has led me into starting my own company, its a once in a lifetime possibility and i am taking the only road or track in my mind that feels right.

I would like to thank all the people that have supported me along the way with my choice and i hope i do not dissapoint you, the track ahead needs dedication and i will without a doubt face problems along the way but this is a challenge i shall take on.

Welcome to Rail Weld Nordic and Rail Weld Institute

Rail Weld Nordic will be supplying the Scandinavian market with competent crews in track building, rail welding and safety.

Rail Weld Institute is a school for the Railway sector training and certifying people in rail welding and other relevant safety courses.

|

|

SAFETY-QUALITY-KNOWLEDGE |